Contact us now to start a partnership that powers progress and innovation in the global coal market.

Executive Head of Marketing

Head Of Domestic Marketing

Head Of Export Marketing

Technical Marketing Manager

High-Quality Thermal Coal for Diverse Needs

Thungela is dedicated to supplying the global market with top-tier thermal coal, characterised by its superior calorific value and consistency. Our coal products are tailored to meet the diverse requirements of power generation, steel manufacturing, and other industrial applications, ensuring that we deliver not just coal, but value and efficiency to our clients’ operations.

Product Highlights

High Calorific Value: Our South African and Australian coal boasts exceptional heat values, ensuring efficient energy production.

Low Impurities: With low ash and sulphur content, our coal meets stringent environmental standards, aiding in cleaner combustion.

Reliability of Supply: Leveraging robust logistics and supply chain management, we guarantee consistent and dependable delivery schedules.

Customisation: We offer a range of specifications to match different technical requirements, ensuring optimal performance for various industrial applications.

Reserves and Resources are shown at 100%

Streamlining Delivery from Mine to Global Markets**

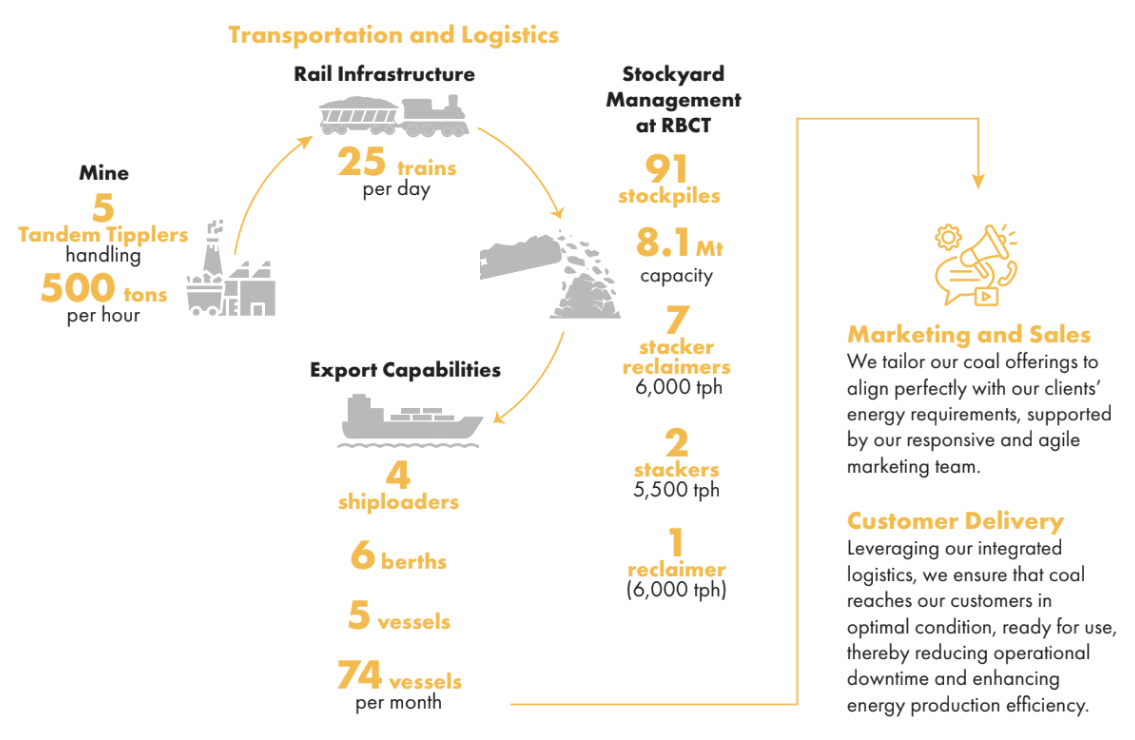

At Thungela, our end-to-end control over the coal supply chain ensures that we deliver superior coal solutions efficiently and reliably to our global customers. Our strategic logistics at the Richards Bay Coal Terminal (RBCT) enhance our capability to meet large-scale demands with precision and speed.

Key Components of Our Value Chain

Mining: High-quality coal extracted from our South African and Australian mines.

Processing: Coal processed to meet precise market specifications for various industrial uses.

Executive Head of Marketing (and TMI Director)

Email: doug@thungela.com

Phone: +971-11-1234567

Head of Export Marketing // Thungela and Ensham (and TMI Director)

Email: doug@thungela.com

Phone: +971-11-1234567